We have now in stock many new Robotics and CNC components:

KITS:

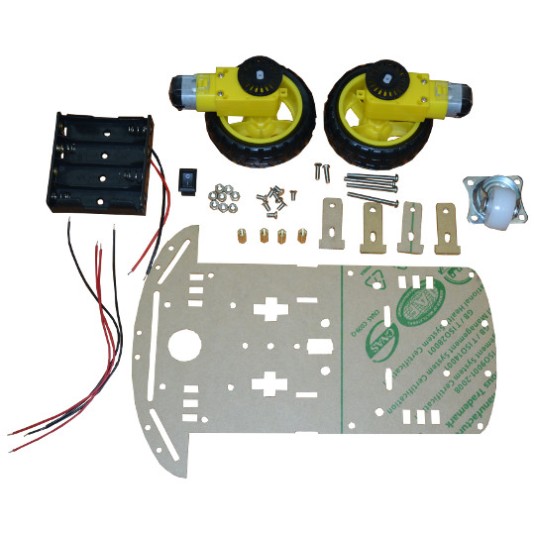

ROBOT-2WDL-KIT Robot platform with two motors with wheels and encoders

ROBOT-LINE-FOLLOW Robot platform with analogue line follower

Micro motors:

MOTOR-200806 12000 rpm brush motor working at 3-6VDC

MOTOR-F1607 small drone motor with fan working on 3-6VDC and speed up to 50 000 rpm

VIBRATING-MOTOR-3X8 small vibrating motor only 3×8 mm size! you can use it to build small bug robot 🙂

Stepper motors:

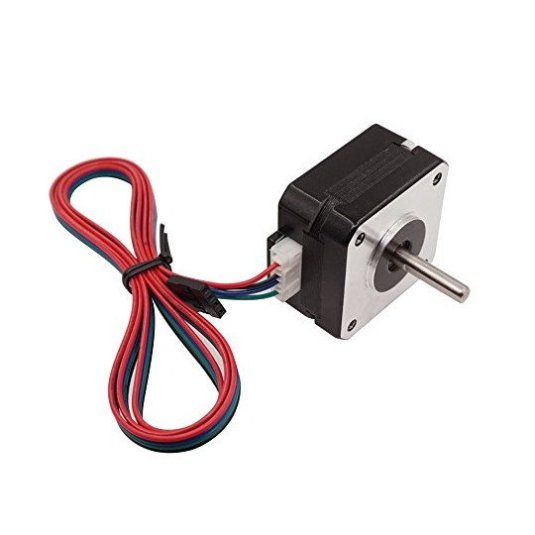

SM-17HS4023 Stepper motor for CNC XY table or 3D printer 42x42x23mm

SM-42HB34F08AB Stepper motor for CNC XY table or 3D printer 42x42x34mm

SM-5VDC-DRV Stepper motor with 1:64 gear and driver!

SM-60SL Stepper motor with 48 mm screw

Robot hand:

ROBOT-GRIP Robot hand which works together with servo motor to open and close

Gear motors:

MG-12V-M4X55 Gear motor with M4x55mm screw can be used for small CNC table or Door lock/unlock mechanism.

MG-6V-1-380 Very compact Gear motor 6VDC 30 RPM can be used for blinder open, close

CARDAN-5X8 and CARDAN-5X5 Free joint for Boat fan or blinders open/close

Linear guides:

LINEAR-GUIDE-400MM Linear slide with 400 mm length

SCREW-T8X8-300MM Trapeziodal screw with brass nut 300 mm

Shaft support:

Wide range of Micro Bearings

GT2 Pulleys and Belts:

Aluminum frame corners for 20×20 , 30×30 and 40×40 profiles:

Strong neodymium magnets 30x10x3 and 10x10x10:

Jul 20, 2018 @ 21:48:36

You should offer propellers for the micro motors in both directions, so one can build a push-pull configuration for quad-, hex-, octa-copters.

Jul 23, 2018 @ 07:50:10

the current propellers can be placed in both directions, but this also can be simply done by reversing the motor directions

Jul 23, 2018 @ 23:24:18

Hmm, turning the propellers upside-down should not make much of a difference on it’s own (at least it doesn’t on my cheap drone propellers), but you are right about driving the motors in reverse direction.

Actually, the best option may be to do both of these at the same time (turn the propellers upside-down + change direction of that motor) – this should make the force equivalent size, but in opposite direction, as the same side of the propeller blades will be the one “hitting” the air.